Welcome to BKS Group!

We are your one stop service center for your Pelletizing & Pulverizing equipment.

Founded in 1983 in Europe, we specialize in the production and grinding of mechanical parts for your pelletizing process, serving the unique needs of compounding and masterbatch companies worldwide.

With over 40 years of experience, we are your trusted partner for the supply of cutting rotors, die-plates and pulverizing discs.

We operate three service centers:

Luxembourg (Europe) => Europe, Middle East, Africa + US region

Thailand => Thailand, Vietnam, Malaysia, Singapore, Myanmar

Indonesia => Indonesia, Taiwan, China, Korea, Japan, Australia

Our customers and partners are companies active in the production of plastic pellets. We are specialized in services for the downstream equipment.

Our Expertise

Pulverizing - Discs & Segments

Whether full discs or segments, we provide a comprehensive service for your pulverizing equipment.

- Full discs

- Segments

- Coatings & lifetime improvements

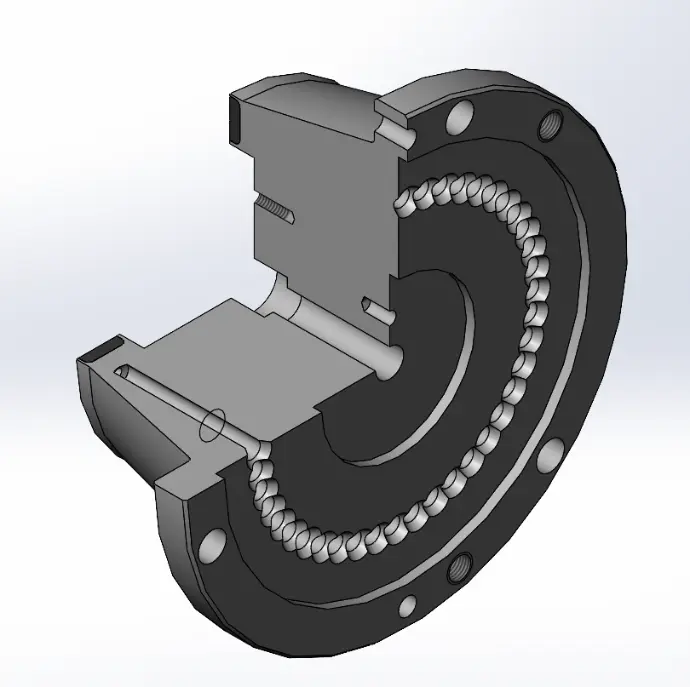

Strand Pelletizing - Rotary cutters

We know and support all types of strand pelletizing units whether it is dry cut or wet cut.

- Rotary cutters & bed knives

- Feedrollers & side limitations

- Bed knife holders

- Flat Extrusion dieplates

- Shafts, bearings, ...

Underwater Pelletizing - Die Plates

We have an extensive knowledge on the underwater pelletizing process whether it is underwater cutting or hot air cut.

- Dieplates (Welded or Brazed)

- Knife holders

- Fly knives (Steel, PM, HSS, Nikro 128)

Our Services

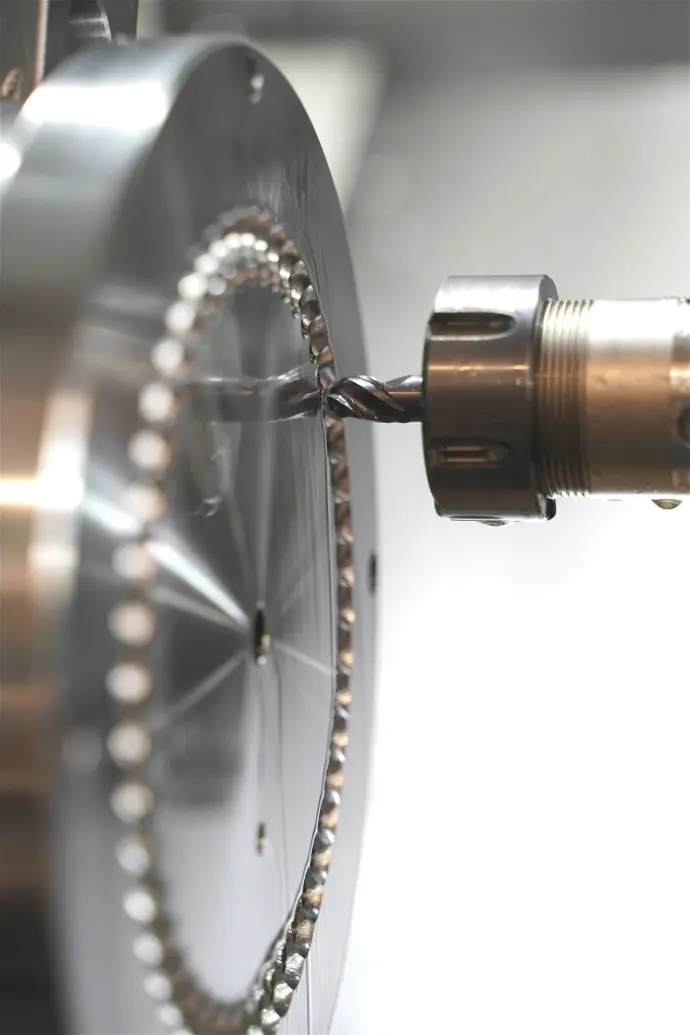

Grinding Service

BKS combines 30 years of expertise together with state-of-the art technology to deliver unmatched grinding services

- Extensive know how on teeth profile, materials, helix angles, ...

- Extensive QC Reports

- Fast lead times & efficient logistics.

- Three service centers wordlwide.

New wear Parts

BKS manufactures high-quality wear parts fully in-house, combining engineering expertise with advanced CNC technology to ensure maximum performance and durability

- Complete in-house process

- Advanced CNC production

- Strict quality control

- Pragmatic & cost efficient.

Consultancy

Beyond manufacturing and servicing industrial knives, BKS also provides specialized consultancy services to help customers optimize their cutting processes, reduce costs, and improve product quality

- Process & wear part optimization

- Budget reduction & cost control

- Reverse Engineering

- Training programs

Why work with BKS?

Industry experience

Decades

of experience in the knife manufacturing and machinery sector specifically focused on the Compounding & Masterbatch production sector.

Tailored Solutions

Our approach adapts to your unique production challenges.

Increased ROI

Optimized machines and proper knife usage lead to cost savings and higher productivity.

Contact Us

At BKS, we believe that proximity is key to excellent service. That’s why we operate three fully equipped service centers strategically located in Luxembourg (Europe), Thailand, and Indonesia.

Each site is staffed with a dedicated local team, ready to support you on both the technical and sales side. Our facilities are equipped with CNC grinding machines to maintain and service your cutting tools

Whether you need technical expertise, sharpening services, or commercial guidance, our teams are on hand to provide fast, reliable, and personalized support.

BKS SARL (Luxembourg)

Zare Ouest 6

4394 Ehlerange

Luxembourg

+352.55.56.47

PT. BKS Indonesia

Jalan Daru 1 - G5-5-1

Delta Silicon 5

17530 Cikarang/Bekasi

Indonesia

+62.21.29.577.642

BKS S.A. Thailand

8/9 Moo 11 Tambol Bangphra

Amphur Sriracha

20110 Chonburi

Thailand

+66.33.005.110